Winding fault electrical system of how to solve?

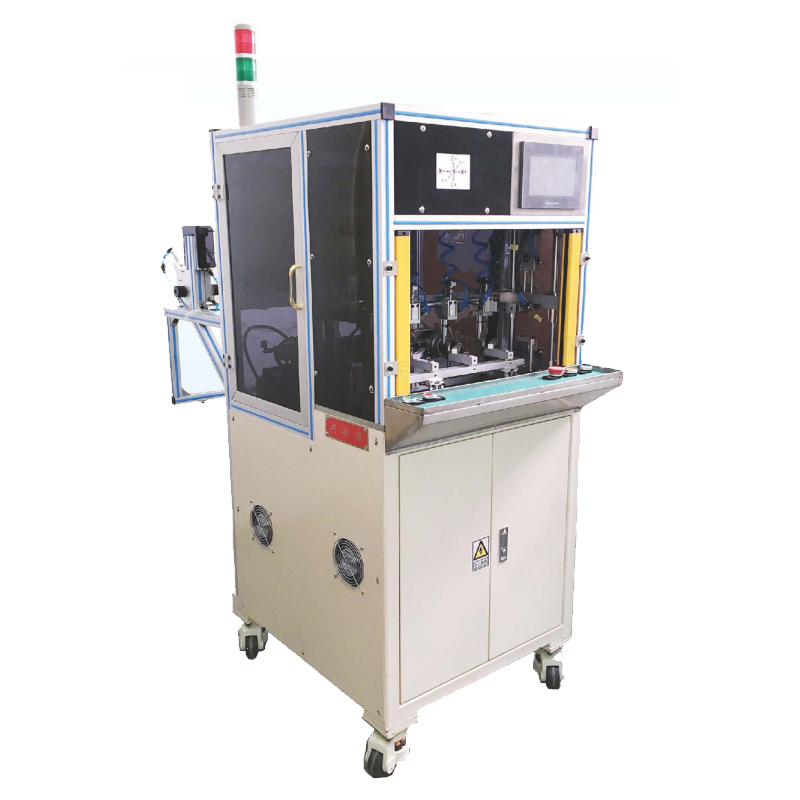

Automatic winding machine with integrated with mechanical, electrical control, photoelectric, pneumatic control, and other types of control system, so its control and maintenance is relatively complex, whether the system failure will affect the normal work of the winding machine, winding machine possible failure, there are many kinds of common faults and processing in this paper, from the electrical system analysis method.

One, such as switches, buttons, control caused by the fault

Switches, buttons, is the most common electrical components in the winding machine, they are responsible for the operation personnel of all instructions into electrical signals to the control system, equipment start-stop, reset, the power on and off, the adjustment of the operation parameters are need them, is not hard to check good switch, button, you can use the multimeter measuring instrument, such as some of the winding machine controller using film button, for these buttons can also use a multimeter to measure, thin-film button is generally equipped with plug, need to measure to pull the plug out first, and then long press the button can be measured, such as electrical fault is the most common, the user should have electrical knowledge, meet with this kind of problem can easily cope with, in equipment use, don't too hard, pay attention to press the button can't use hard objects such as a screwdriver tools, found loose button or strange timely notify the maintenance personnel.

Second, electrical parts damage caused by the fault

Common electric actuating parts are in winding machine controller, inverter, spindle motor, stepping motor, electromagnetic brake, electromagnetic valve, etc., these are also at the heart of the winding machine electrical components, they play an important role in the performance of these parts at the same time also determines the working performance of the winding machine, the controller is the brains of the winding machine which is responsible for control power, wiring, etc., the current common winding machine controller has two kinds, one kind is by integrated suppliers of general controller, another kind is their own research and development of the controller, the controller generally common failures are high voltage control part and buttons, these problems the average user can't own to solve, need to inform the manufacturer to repair; Frequency converter fault is also more common, can be judged by looking at the inverter display interface failure; Motor fault user classes in use process should pay attention to check for sound, the motor temperature rise is normal, equipment used to eliminate overload; Brake belong to wearing parts, use after a period of time in winding machine should timely adjust, be replaced when necessary.

3, electric control system malfunction caused by improper setting

Belongs to soft fault system set improperly, coiling machine a complex set of control system and control program, improper setting can also cause failure, the user must first understand the main points of the instructions before use winding machine, the common improper setting of winding and row line direction error, row line width more than equipment scheduling, wire diameter and coil winding machine speed mismatch, stepping error and so on a series of displacement of the unit, there are many manufacturers currently provide operation training, use the unit should be chosen to study, to avoid change after winding process will not set the winding machine of this kind of problem.