Brushless motor winding machine

Product attributes

- Classification:4 Labour brushless motor winding machine

- Product no. :YL-208

- Number of visits:0

- Date of issue:2020-03-27

- Product overview

Product name: brushless motor winding machine (4 Labour)

Product range:

Stepper motor, brushless motor, fan motor, no hakaze fan motor, servo motor and other kinds of brushless dc motor.

Machine:

This machine is a four location model; Move up and down through the nozzle and the rotation of the core, according to arbitrary path winding. Thus with a change computer winding program corresponding to different core stack thickness and the number of different core winding. For four axis synchronous lined up wound, and can meet the requirements of winding high special process; Machine adopts servo precision positioning, automatic wind thread tail, lines, automatic winding, automatic line, automatic indexing, automatic GaJian, achieve the optimal cost-effective equipment.

Features:

1. This machine is a four head type, realize the optimal cost-effective equipment.

2. The machine high commonality, be applicable to the production of various kinds of brushless motor.

3. At the same time of high speed winding machine, can the row line process control and processing.

4. Automatic thread thread tail, automatic winding, automatic line, automatic indexing, automatic GaJian.

5. A digraph was served motor accurate positioning, coiling, platoon line, inversion.

6. The use of advanced technology for the man-machine interface control system, the operation is simple to learn.

The machine parameters:

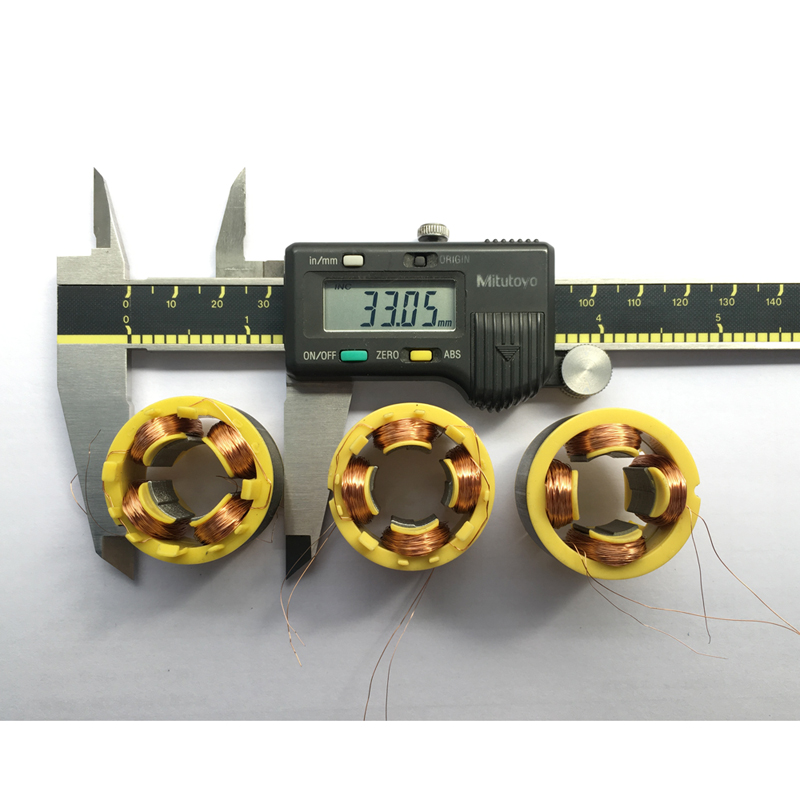

Optimum winding diameter | From 0.08-0.6 mm (in accordance with the wire diameter selection line frame) | Number of work | 4 only |

| Outer diameter of the stator | From 20 mm - 100 mm (greater than this parameter can be customized) | Stator product thickness | 5-70mm |

Servo drive | A set of 3000 w / 5000 w | Transfer servo | 2000 w, 2-4 sets |

| Rows of servo | 2 sets of 750 w | Air pressure | 7kg/cm2 |

The power supply | Three phase 380 v 50/60 hz | Installation dimensions | About 920 * 1760 * 910 w h l |

The weight of the | About 500 kg |